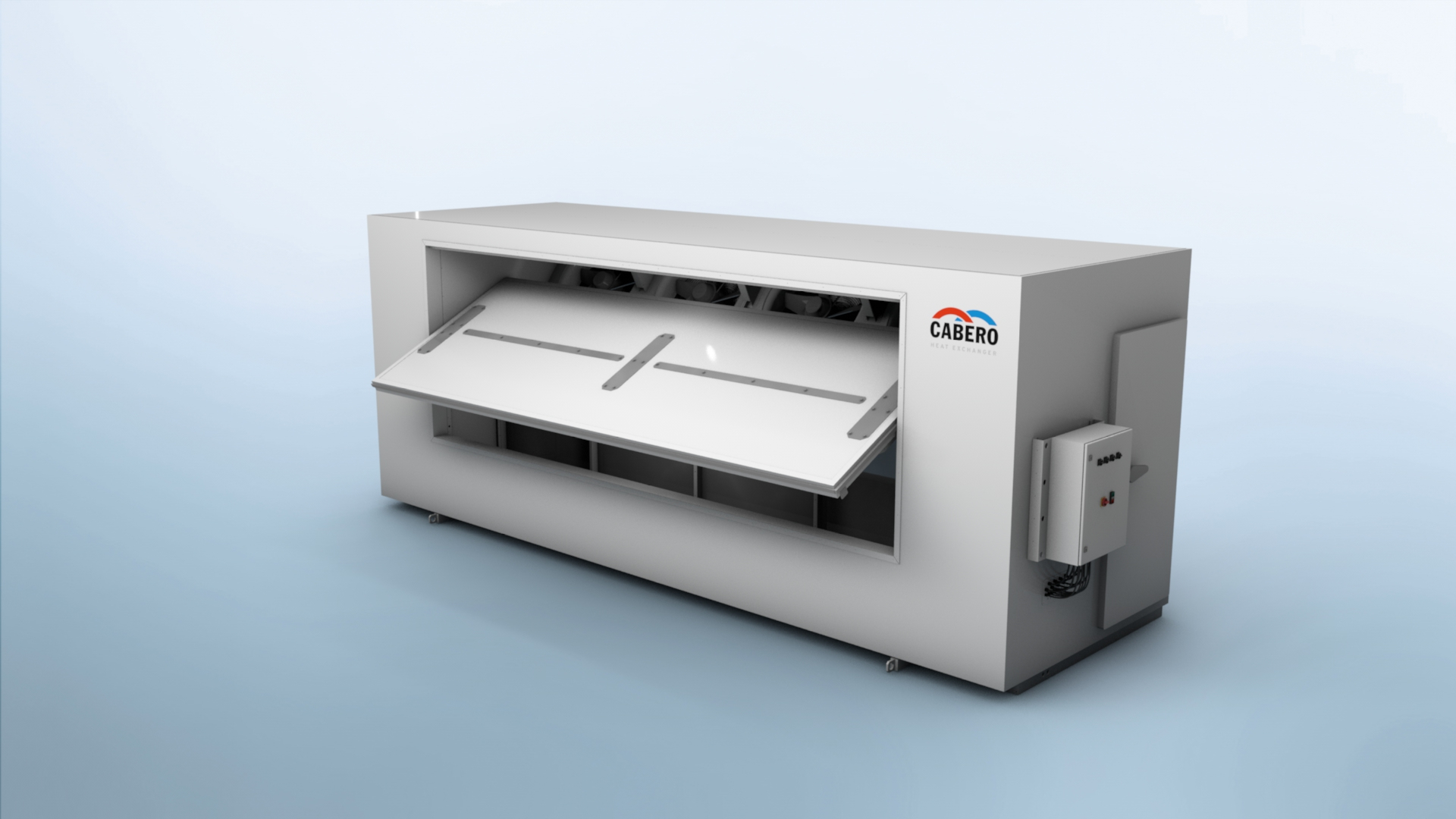

For separate installation away from the storage facility

Operation

The evaporators or air coolers are installed in the heat-insulated cells at the factory. These heat-insulated cells are installed outside the storage room and "flanged" to the building with a breakthrough on the air side. As a result, the connection can be separated from the heat-insulated cell to the cooling chamber in the defrosting process by means of the folding system.

The temperature of the circulating air corresponds to the type of defrosting - here we distinguish between brine and hot gas defrosting as well as electrical defrosting. This allows service and maintenance work under recirculated air temperatures.

Energetische Effizienz

The flap system is closed before the defrosting process. Thus resulting clouds of steam, thereby resulting ice formation in the storage room can be completely ruled out. During defrost, heat and moisture entry into the storage room (fridge) is avoided, thus achieving maximum energy efficiency.

Optimal space utilization concept and static advantages

Due to the external setting-up of the insulating cells, the static additional load on the building can be neglected, in particular in the case of insulating heaters. This costly structure of the building is avoided. For modernization or renovation of buildings, these systems are able to guarantee very short installation times due to the factory assembly.