EXAMPLES FOR OUR ACTIONS -

REFERENCES OUR ABILITIES

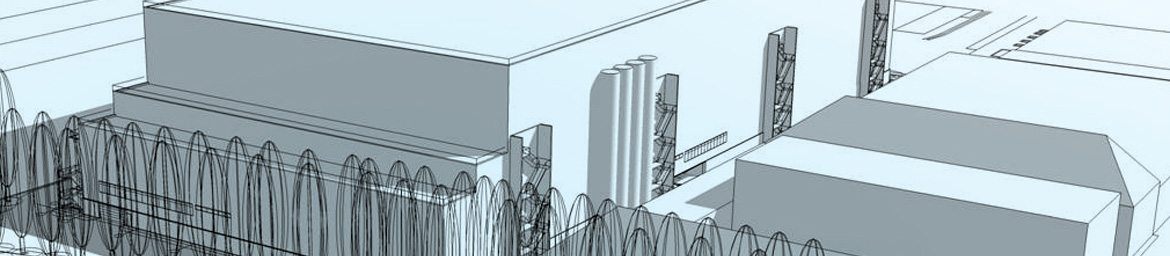

BMW Group Munich factory

The highly efficient integrated Paint Process Technology is used in production at the Munich factory of the automotive manufacturer. The particularly environmentally friendly system has to be cooled with equally high efficiency: This is provided by CABERO heat exchangers with 24 MW output. A special technical feature also provided by CABERO: All systems can be supplied silicone-free on request.

Large Data Centre from e-shelter.

E-shelter plans, builds and operates high-performance computing centers with the highest demands on physical security and operational fail-safety. With a total area of 60,000 m2, the main location in Frankfurt / Main is Europe's largest single computer center location. Here and in eight other e-shelter locations, CABERO coolers contribute to the data security of financial services and telecommunications companies as well as IT and cloud service providers.

RED BULL ARENA - TRAININGSZENTRUM

Opposite its Red Bull Arena, the ambitious football club Rasen- Ballsport leipzig built a state-of-the-art training centre for the training needs of all professional and junior players. To provide the players with a constant training climate, two dry heat exchangers from CABERO, each with 425 kW cooling output, support the cold air supply for the extensive facility.

KLINIKUM RECHTS DER ISAR

The “Klinikum rechts der isar” hospital at the Technical University of Munich is a centre for state-of-the-art medicine: CABERO provides an indispensable element of the cooling technology in this complex with different heat exchanger models from table versions to V-block units. In recent years alone, units with an output of 8 MW were installed, all meeting the very strict noise emission regulations.

THAI FOOD - KABIN BBURI

This facility manufactures fish products for the international market. It therefore requires the air to be cooled reliably with industrial evaporators. A work environment practically free from draughts was a top priority to increase productivity by reducing sick days among employees. The total output of the system, which uses the refrigerant NH³, is 1200 MW.